Butt hinges come in many sizes and configurations to accommodate most door installations. We dive into the two grades of butt hinges, the typical “anatomy”, the various types of butt hinges and their applications, what door attributes we look for when specifying butt hinges, and common questions / scenarios we may ask about when working on your project.

Residential hinges are thinner gauge hinges that are typically manufactured by stamping the shape out of a material and then rolling it to create the barrels. These hinges can be found in big box home improvement stores and pre-hung doors from a millwork. A common characteristic of residential hinges is the corners having a radius edge. A 5/8” radius corner is most common for ease of installation. A 1/4” radius corner hinges are available, but less common.

Architectural hinges are heavier gauge versus the residential counterparts. They are manufactured by extrusion or casting methods.

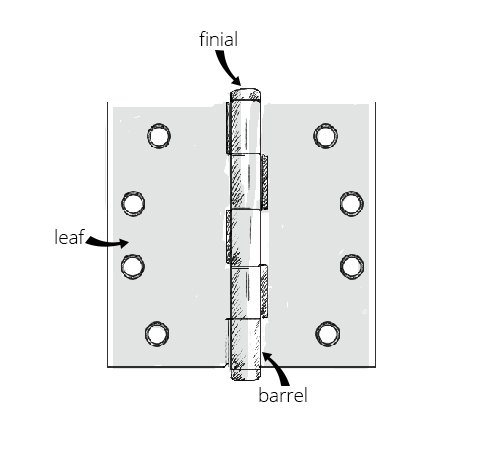

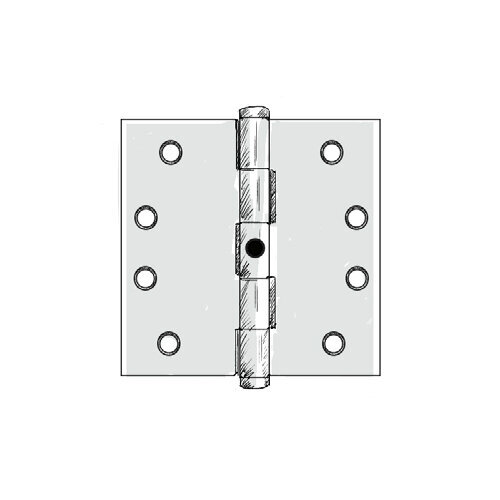

Whether residential or architectural, construction will be similar for both types of hinge. This includes two leafs, one with three knuckles and the other with two, connected by a steel pin that has been installed in the barrel, and capped off with finials on both ends. Decorative finials give an extra decorative aspect to the hinge. See the diagram below.

Anatomy Of A Butt Hinge

Barrel – Also referred to as the butt. Typically round and houses the pin that connects both hinge leafs.

Leaf – Flat body of hinge that are fastened to door and jamb.

Finial – Decorative piece that screws to top and bottom of barrel.

To the right: a five knuckle, plain bearing hinge with button finials.

Types OF Butt Hinges

Beyond size, corner style, and gauge, there are several variations of butt hinges that are designed for extra strength, additional security, and installations that require the door to swing differently from typical applications.

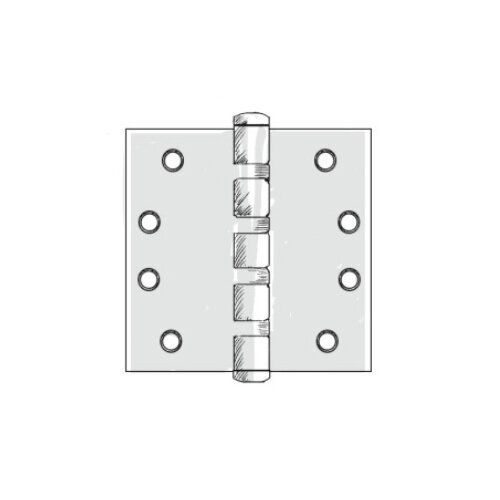

Ball Bearing Hinges

Two or four ball bearings are installed along the barrel of the hinge for additional strength and a longer lifecycle when installed on especially heavy or 2-1/4”+ thick doors.

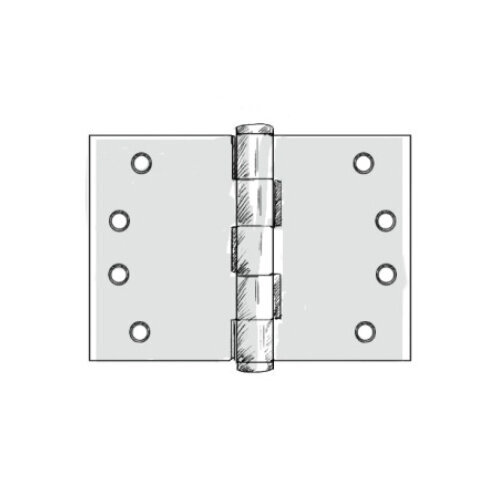

Wide Throw Hinges

Intended for doors intended to travel 180 degrees to sit flush against wall and/or for doors that need to travel around heavy or ornate door casings. 4” Tall x 6” Wide is most common size for wide throw hinges.

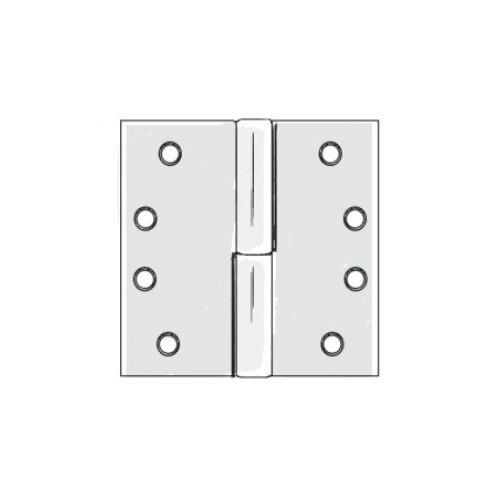

2 Knuckle Lift Off Hinge

Also commonly known as paumelle hinges. The 2 knuckle lift off hinges are handed and do not accommodate finials. Butt style life off hinges can have standard or square barrels.

Non-Removable Pin

Most often used for exterior doors that swing outward (the barrels on the exterior of the building), a set screw is drilled into the hinge barrel and pin, preventing the door being taken off the hinges.

Prep & Installation

Hinges do not bear the weight of the door evenly or simply hold the door on the jamb. The position of each hinge determines the roll they play when installed. The top hinge carries the vast majority of the weight of the door and the bottom hinge prevents the door from coming out of plane. Depending on the height of the door the middle hinge(s) provide structure, rigidness, and help prevent reverberation when the door is closed.

Quantity Of Hinges

We specify the number of hinges needed based on the height of the door.

-

7’6” (90”) and below: 3 hinges

-

7’6” (90”) to 8’6” (102”): 4 hinges

-

8’6” (102”) and above: 4 hinges plus one hinge every additional 18”

Recommended Hinge Size Per Application

-

3” x 3”: screen doors and cabinetry

-

3-1/2” x 3-1/2”: 1-3/8” thick doors

-

4” x 4”: 1-3/4” doors

-

4-1/2” x 4-1/2: 2-1/4” doors

Screw Patterns

Screw patterns are NOT universal!

-

D Shape: found on most architectural grade

-

Zig-Zag: typically found on cheaper, stainless steel hinges.

-

ANSI Prep: Sets the gauge, number of holes required per hinge, and weight restrictions based on hinge size.

D shape screw patterned hinges can sometimes be used over a previous zig zag installation. Two of the screws on the D shape hinge should follow the zig-zag pattern and two new holes will need to be drilled. The caveat here is that installers need to be careful on steel/aluminum doors and jambs due to the material.

Measuring A Hinge

Lay or open hinge so that leafs are flat. Measure height first, then width, keeping in mind that most hinges are square.

Specifying Hinges

At Chicago Brass, we have our go to hinges for every situation. Merit Metal hinges tick all of the boxes for us, but we’ll suggest what’s most appropriate for your project. If your project is using Rocky Mountain Hardware or Sun Valley Bronze trim, we’ll most likely suggest using those hinges as they are sand cast and carry the same characteristics as their trim counterparts.

For those projects with a more obscure finish, we may suggest Classic Brass and for projects on smaller budget, we often specify Deltana or Baldwin.

When it comes to “Good, Better, Best”, we look for the following:

-

Finishing / Finish Availability

-

Consistency

-

Lead Time / Availability

-

Customization? Wide throw, different sizes, etc.