Option A All Prep Done On-Site

Steps

-

Door supplier ships doors and jambs, less any sort of prep.

-

On-site installer does all prep work.

Pros

Leaves no room for miscommunication or misinterpretation.

Avoids concerns of less than stellar prep work at the door shop.

All hardware installed post-painting.

Cons

Typically, site prep work is more time consuming and expensive than what can be done in a controlled shop environment.

Not all carpenters are capable of a quality hardware install.

Option B All Prep Work In-Shop

Steps

-

Door supplier is provided with all prep instructions.

-

Doors are shipped with all required drilling so on-site installation work is assembly only.

-

Installer attaches the hardware to the door.

Pros

Typically quicker and less expensive than if done on-site.

If a strong door supplier, the preps will be more accurate.

Cons

If the door supplier is not the greatest, the preps can be less than accurate.

Once door order is singed off on, changes to the hardware package are rarely possible.

If a door supplier is not familiar with the prep required, they are often unwilling to do it. Some hardware installed pre-painting.

Communication within the supply chain must be strong.

Option C Combine Aspects Of Options A & B, Prep Work Done In-Shop & On-Site

Steps

-

Door supplier is provided with all prep instructions.

-

A discussion is had with the GC detailing what is being installed in the shop and what is being done on site, consuming where the face boring is least.

-

We suggest all hinges, strikes, lock bodies, and roller latches are prepped for. All face boring is done on-site.

Pros

A combination of the pros of both A and B, but diminished.

The lock/latch prep and hinges prep are the most time consuming, where the face boring is the least, but requires the most accuracy. This plays to those characteristics.

Cons

More time required by specifier than Option A.

Face Prep

Edge & Face Prep

Strike Prep

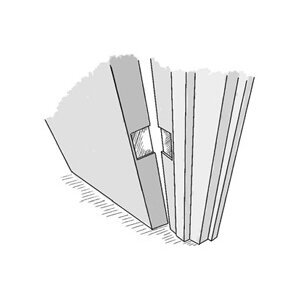

Hinge Prep

Schedule includes door preparation instructions for Option B. Reference final hardware schedule only, no drafts.